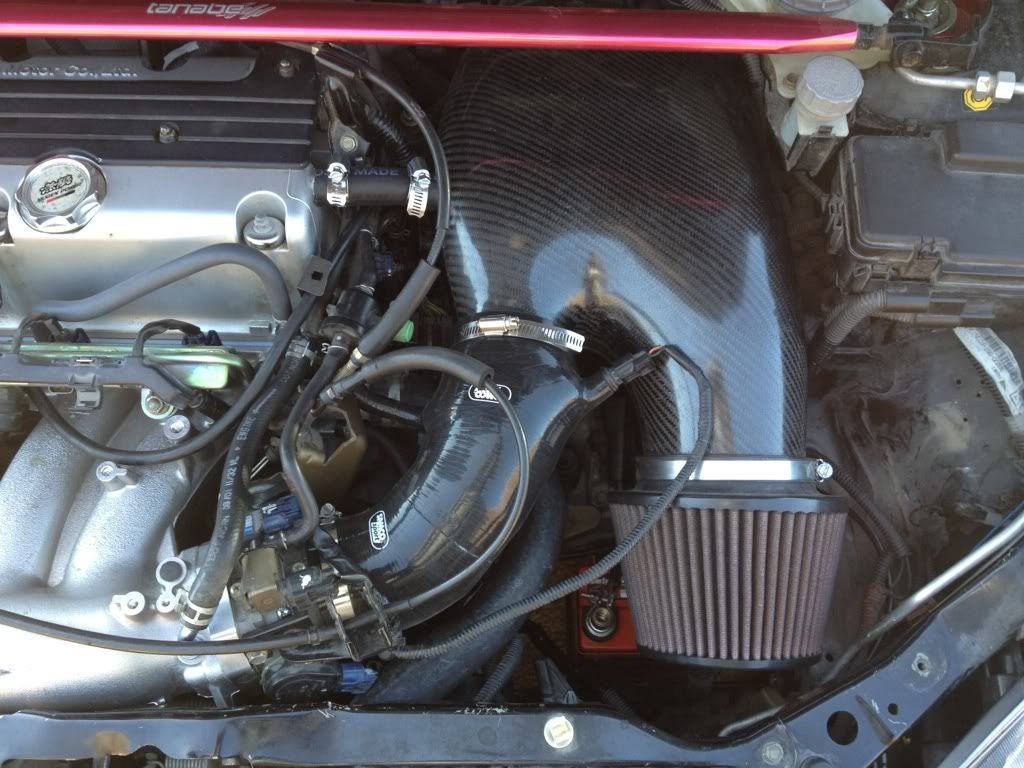

The following weekend came the good stuff. I will note here the Power Chamber offers a noticeable improvement in mid range acceleration over the AEM intake. But now, enter the manifold...

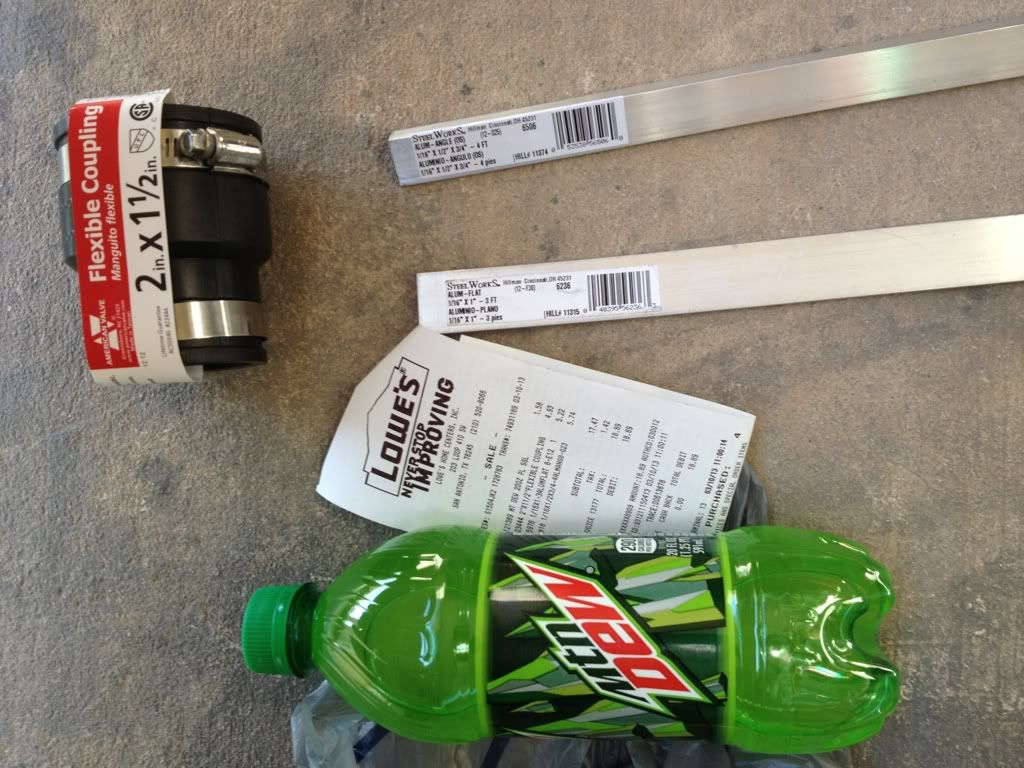

RBC kit courtesy of Daniel, the originator.

I did a little port matching of the throat and smoothed out the runners. What God awful sand casting these manifolds have.

Now the install itself was not all too complicated. I was able to get her bolted up in a couple hours using little more than some online research and the Helms PDF for torque specs.

This was where I was at.

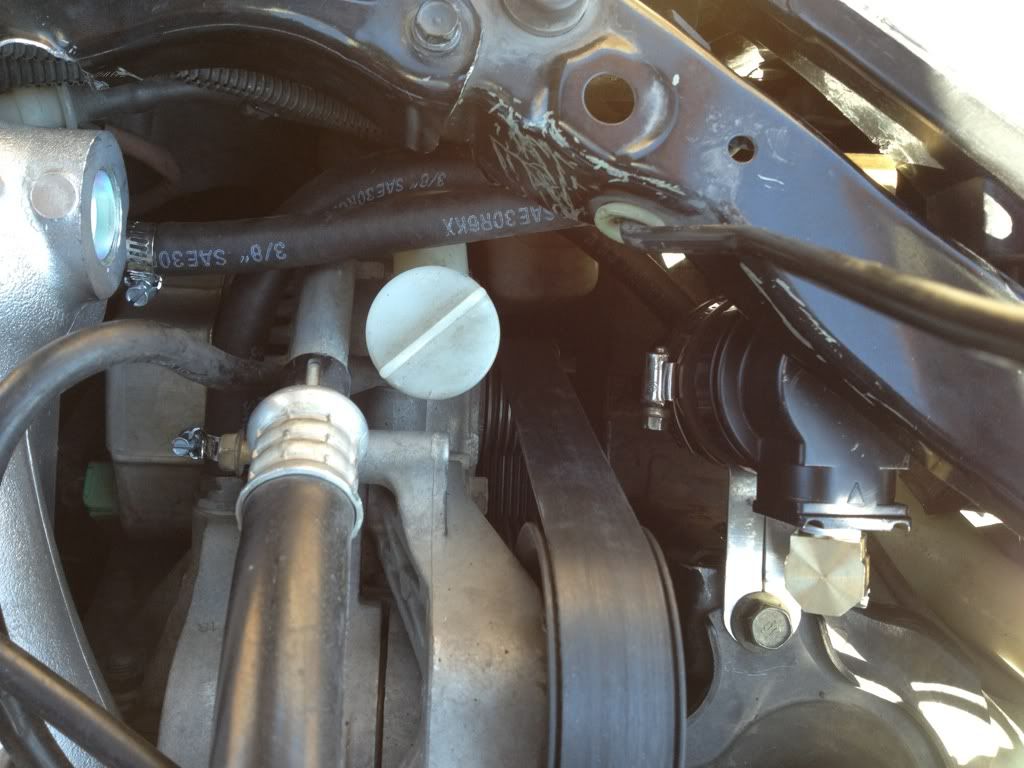

Did some ghastly trimming with my Dremel to the upper radiator support just to get tge hood to close right.

Reply With Quote

Reply With Quote

Bookmarks